If you manage a building in Scotland, whether it’s a care home in Lanarkshire, a hotel in Glasgow, or an office block in Edinburgh, there’s a good chance you’ve got fire dampers hidden away inside your ductwork. And there’s an equally good chance they haven’t been tested recently enough.

Fire damper testing in Scotland isn’t optional. It’s a legal requirement. Under BS 9999 and the Fire (Scotland) Act 2005, every fire damper in a non-domestic building must be inspected and tested at least once a year by a competent person. If yours haven’t been checked in the last twelve months, you’re already behind.

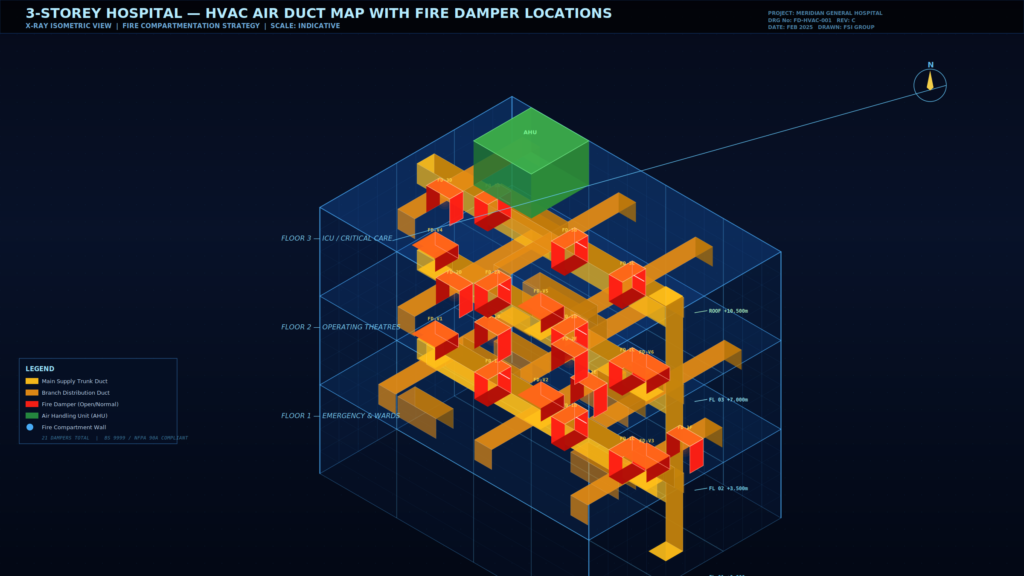

Here’s the short version: fire dampers are passive fire safety devices installed inside ventilation ducts. When a fire breaks out, they’re designed to close automatically and stop flames and smoke from spreading through the building’s ductwork. They’re one of those things you never think about… until they don’t work. And by then, it’s too late.

This guide covers everything you need to know about fire damper testing in Scotland. We’ll walk through what dampers actually do, why annual testing is required by law, what happens during an inspection, what to watch out for, and what could happen if you let compliance slip. If you’re a facilities manager, estates manager, or building owner, this one’s for you.

So, what exactly is a fire damper?

Think of fire dampers as gatekeepers inside your ventilation system. Every commercial building has ductwork, those metal channels that carry heated or cooled air around the building. The problem is, those same channels can carry something far more dangerous: fire and smoke.

Fire dampers are installed at the points where ducts pass through fire-rated walls, floors, and ceilings. These walls and floors are designed to contain fire within a specific area (known as a fire compartment), but without a damper at each duct penetration, the ductwork creates an open pathway for fire to travel between compartments. It’s a bit like having a fireproof door but leaving a window wide open.

There are two main types. Mechanical fire dampers use a fusible link – a small metal component that melts at a set temperature, typically around 72°C. When the air inside the duct gets hot enough, the link melts and the damper’s blades or curtain drops shut under spring tension. Motorised fire dampers, on the other hand, are wired into the building’s fire alarm system and close electronically when the alarm is triggered.

Both types do the same job: they seal off sections of ductwork to stop fire and smoke from moving through the building. In a care home full of vulnerable residents, or a hotel full of sleeping guests, that containment can be the difference between a manageable incident and a catastrophe.

The law is clear: annual testing is not negotiable

In Scotland, fire safety in non-domestic premises falls under the Fire (Scotland) Act 2005 and the Fire Safety (Scotland) Regulations 2006. These place a duty on the “duty holder”, typically the employer, building owner, or whoever has control of the premises, to carry out a fire risk assessment and maintain all fire safety systems. Fire dampers are firmly within that scope.

BS 9999:2017, the British Standard code of practice for fire safety in buildings, spells it out plainly. It states that all fire dampers should be tested by a competent person at regular intervals not exceeding one year, and repaired or replaced immediately if found to be faulty. Spring-operated dampers in dusty or greasy environments such as commercial kitchens, for example, may need even more frequent checks.

On top of that, the Building Engineering Services Association (BESA) has published Technical Bulletin VH001, which provides detailed guidance on fire and smoke damper maintenance. It’s become the industry reference document and covers everything from testing procedures to reporting standards. If your testing contractor isn’t following VH001, that’s a red flag.

And let’s not forget Health Technical Memorandum HTM 03-01, which applies specifically to healthcare premises. If you’re managing a hospital, clinic, or NHS facility in Scotland, the testing expectations are even stricter. Annual testing is the absolute minimum. Some trusts require it more often.

The bottom line? Whether you’re running a nursing home in Hamilton or a student accommodation block in Glasgow, the law expects your fire dampers to be tested every year. There’s no grey area.

What actually happens during a fire damper test?

If you’ve never been involved in a fire damper inspection before, here’s a rough idea of how it works. It’s more involved than people expect.

First, the engineer needs to locate every damper in the building. This sounds straightforward, but in older buildings it can be quite difficult. Some dampers don’t appear on any plans. Some are hidden behind plasterboard. Others are in ceiling voids that haven’t been opened in years. A good testing company will work from your asset register and flag any gaps or missing dampers they come across.

Once a damper is located and accessed, usually through a duct access panel or by removing ceiling tiles, the engineer carries out a visual inspection. They’re checking for corrosion, dirt and dust build-up, damage to the blades or frame, missing or damaged fusible links, and any obstructions that might prevent the damper from closing properly.

Then comes the drop test. For mechanical dampers, this means removing the fusible link and releasing the spring mechanism so the blades drop shut. The engineer checks that the damper closes fully and locks into position without any obstruction. For motorised dampers, the test involves activating the motor to confirm the blades open and close as intended.

After testing, the damper is reset. The fusible link is also refitted (or replaced if damaged) and any cleaning is carried out. Photos are taken before and after. This is standard practice under VH001 and provides evidence of the damper’s condition at the time of inspection.

Finally, the engineer produces a detailed report. Each damper gets its own entry, including its location, type, condition, pass or fail result, photos, and any recommended remedial work. This documentation matters. It’s what you’ll need to show an insurer, an auditor, or a fire safety officer if they come knocking.

Warning signs your dampers might be failing

Fire dampers don’t give you many clues when they’re struggling. They sit inside ductwork, out of sight and out of mind. That’s partly why regular testing is so important as you can’t rely on spotting problems yourself.

That said, there are some things to watch for. If your HVAC system has sudden unexplained changes in airflow or unusual noises coming from the ductwork, a displaced or partially closed damper could be the cause. Visible rust or corrosion around duct access panels is another warning sign, especially in older buildings or environments with high humidity.

During testing, the most common issues engineers find include corroded springs that no longer have enough tension to close the blades; fusible links that have been painted over (surprisingly common during refurbishment projects); debris and dust build-up jamming the blade mechanism; dampers installed backwards or without proper fire stopping around the frame; and access panels that have been sealed shut or built over, making future testing impossible.

In commercial kitchens, grease accumulation is a particular concern. Grease can coat damper blades and prevent them from closing, which is why kitchen extract systems often need more frequent attention. If your building has a commercial kitchen, it’s worth thinking about fire damper testing alongside your TR/19 kitchen canopy cleaning schedule.

What happens if you don’t comply?

Let’s be blunt about this. The consequences of ignoring fire damper testing are serious.

The Scottish Fire and Rescue Service has the authority to inspect non-domestic premises and enforce compliance with fire safety legislation. If they find your fire dampers haven’t been tested, or that your fire risk assessment doesn’t account for them, you could face an enforcement notice requiring immediate action. In serious cases, they can issue a prohibition notice that means restricting or shutting down the use of all or part of your building until the problems are fixed.

The financial penalties are steep. Minor fire safety offences can result in fines up to £5,000. For more serious breaches, courts can impose unlimited fines. And in the most severe cases where non-compliance puts people at genuine risk of death or serious injury the duty holder can face up to two years in prison. These aren’t theoretical penalties. Fines for fire safety breaches have increased sharply in recent years. The average penalty rising by more than a third since the Grenfell Tower tragedy.

Beyond the legal risk, there’s the insurance question. Most commercial insurance policies assume you’re complying with fire safety regulations. If a fire occurs and your dampers haven’t been tested, your insurer may refuse to pay out. That could be the end of the business entirely.

And then there’s the human cost. Fire dampers exist to protect people. In a care home, a hospital, or a school, these are environments where the people inside may not be able to evacuate quickly on their own. A damper that doesn’t close could mean fire and smoke spread through the building faster than anyone can respond. That’s not a risk worth taking.

How KA Facilities Management can help

At KA Facilities Management, we carry out fire damper testing across Glasgow, Lanarkshire, and the wider Central Belt of Scotland. Our engineers are trained to BESA standards and hold accreditations including IFSM, IOSH, and NEBOSH qualifications. We understand the specific requirements of the Fire (Scotland) Act 2005, BS 9999, and BESA VH001 and we apply them on every job.

Here’s what you get when you work with us. We carry out a thorough visual inspection and functional drop test on every damper. We provide detailed photographic reports with pass/fail results and recommendations for any remedial work. If dampers need repair or replacement, we can handle that too. And we offer scheduled maintenance plans so you never have to worry about missing your annual test.

We work with care homes, hotels, hospitals, schools, offices, and industrial sites. Whether you’ve got ten dampers or five hundred, we’ll put together a plan that fits your building and your budget.

What sets us apart is that we’re not just a fire damper company. We offer a full range of compliance services from fire risk assessments and PAT testing to legionella risk assessments and gas tightness testing and certifications. That means you can consolidate your compliance work with one trusted provider instead of juggling multiple contractors.

If you’re not sure when your dampers were last tested, or you’re looking for a reliable contractor to take this off your plate, get in touch. We’ll give you a straight answer and a fair quote.

Ready to book your annual fire damper test? Contact KA Facilities Management today on 01698 678689 or visit our contact page to request a quote.

Frequently Asked Questions

Under BS 9999:2017 and the Fire (Scotland) Act 2005, fire dampers must be tested at least once every twelve months by a competent person. Buildings with dusty or greasy environments such as those with commercial kitchens may require more frequent testing. Healthcare premises under HTM 03-01 may also have stricter schedules.

BS 9999:2017 is the British Standard code of practice for fire safety in the design, management, and use of buildings. It sets out the requirements for fire damper installation, testing, and maintenance. Compliance with BS 9999 is effectively a legal expectation under fire safety legislation, and it’s what insurers and fire officers will look for when assessing your building.

Yes, and it often makes sense to do so. Combining fire damper testing with related services like TR/19 kitchen canopy cleaning, fire risk assessments, or PAT testing can reduce downtime and cut costs. KA Facilities Management offers a full suite of compliance services across fire safety, gas safety, and water hygiene, so you can coordinate everything through a single provider.

If a damper fails, it should be repaired or replaced immediately. BS 9999 is clear on this point; faulty dampers must not be left in service. Your testing contractor should provide a detailed report outlining the issue and the recommended corrective action. At KA Facilities Management, we can carry out repairs and replacements on the same visit where possible, minimising disruption and getting your building back to compliance quickly.

The duty holder is responsible. Under Scottish fire safety law, this is typically the employer, building owner, or whoever has control of the premises. If you’re a facilities manager or estates manager, fire damper testing almost certainly falls within your remit. The actual testing must be carried out by a competent person with the right training and qualifications.

Comments are closed